The Power of Automation in Composite Manufacturing

Automation is a growth lever for thermoplastic composite part manufacturing in aerospace. High-performance polymers, such as LMPAEK, and new processing technologies have converged to offer opportunities for aircraft OEMs and Tier suppliers to use lightweight composite to increase throughput, reduce defects, and improve efficiency in a manner that may, in turn, reduce production costs.

The light-weighting and mechanical benefits of composite technology are widely accepted, as demonstrated by their steady growth in the manufacture of aircraft since their introduction and now projected to reach $465 million by 2026. Thinking ahead, composites have more to offer the industry with respect to system cost reduction and increased throughput, especially with regards to thermoplastic composite (TPCs) unidirectional tapes (UDT). It can be argued that TPCs are a more forgiving material to manufacture. They can be reprocessed and do not carry the risk of an exotherm are less likely to suffer from foreign object debris. While offering improvements in speed, cleanliness, and scalability.

Consistent Format: Unidirectional Tapes

Thermoplastic composite unidirectional tapes (TPUD) are frequently leveraged for automated production methods because the homogeneous format - consistent width, thickness, and low void content offer a level of predictability when produced at scale. Today, we have a variety of out-of-autoclave manufacturing methods specifically designed to leverage the full potential of TPC.

For example, the following are all highly automated and commercially available manufacturing techniques:

- Automated Tape Laying (ATL) and press consolidation

- In-situ Automated Fibre Placement (AFP)

- AFP and Vac Bag Only (VBO)

- AFP and oven consolidation

- Continuous Compression Moulding (CCM)

- Fibre Patch Placement (FPP)

- Compression moulding

- Braiding

However, automated production methods are not without challenges. Manual processing has been the dominant production method since composites were introduced to the aerospace industry. Switching to an automated process may be considered a natural evolution, but it takes time to validate processes and inspection techniques and for them to be documented in specifications. The challenge now has become selecting the right material for the right application.

Why designing with TPCs is different from designing with metals

For design engineers, designing with metals is a different field of knowledge than composites, which are anisotropic (i.e. directional). If you need isotropic properties (i.e. same when measured in all directions), then you might ask why use an anisotropic material. The answer lies in two parts:

- Firstly, the density differences between carbon composites at ~1.6 g/cc vs common aerospace-grade metals like aluminium at ~2.8 g/cc and titanium at 4.4 g/cc. The composite is ~1/3 lighter than aluminium and ~2/3 lighter than titanium. But that does not tell the whole story.

- Secondly, you need to look at the specific strength of a material, which is commonly referred to as the strength-to-weight ratio. Aluminium 6061-T6 and Titanium (Grade 5) 6AI-4V have a strength-to-weight ratio of 107 and 214 respectively. While a composite can offer a very impressive 1515. This makes for a very compelling case for a composite even when loads are applied uniformly. An important distinction here is that the composite strength is highly directional.

In applications where the load cases are not applied uniformly, composites and their anisotropic properties offer the ability to customize. With these tailored properties, the laminates can be thinned down even further to deliver weight savings beyond what can be provided by their quasi-isotropic and metallic counterparts. Hence, the incredible value of the design freedom afforded to engineers that have ATL or AFP production equipment at their disposal.

Optimizing for both performance and manufacture

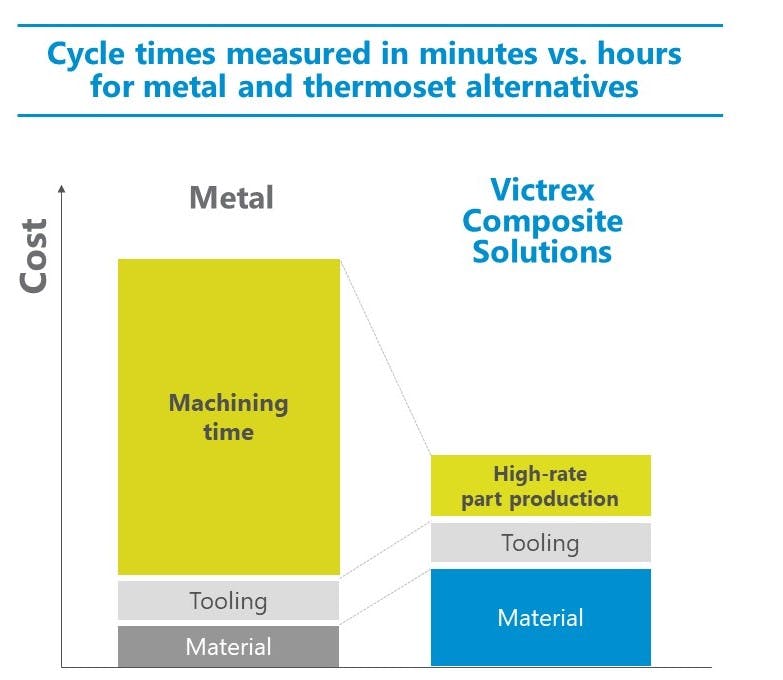

The manufacturing process needs to be considered at the beginning of the part design. Design for manufacturing can be used to inform the design for the application. Processing knowledge is critical to achieving the project objectives on time and on budget. For example, in the hybrid moulding process, part design drives tooling design, and there is an iterative design process to optimize the part for both performance and manufacturability. The fundamental difference between designing composite parts versus metal parts is that for composite parts, the material is expensive, time is not (due to fast cycle times), for metal design, it’s the opposite, the material is relatively inexpensive, and time is a significant cost. Consequently, you must choose your partners wisely to ensure they have a broad understanding of available TPC manufacturing technologies. This understanding will help the design engineers select the right process and material combination for the application.

Availability of Qualified Materials

Another historical barrier to the adoption of TPC’s is a qualified materials database. Metals used in aviation for example have the benefit of over 100 years of knowledge and have since been standardized and mostly commoditized. When it comes to thermoplastics, it is more complex because rather than creating a database for a specific material, you require data for the specific TPC material and manufacturing process. Although this obstacle continues to become less significant as material and process standards become available it demonstrates the importance of the partnership approach to design and manufacture to deploy TPC solutions effectively. The question becomes: do we invest in mature materials and technology likely at the end of its lifecycle, or cross the chasm to a new material and process combination that holds the promise for future efficiencies? If OEM investment is an indication, I suspect the latter.

A Bright Future for TPCs

The future of composites in aerospace is looking brighter than ever. With the increasing availability and adoption of automated production technologies for TPCs, we are seeing a rise in composite usage across various aircraft platforms including commercial, AAM, and rotorcraft. As material qualifications continue to progress and the industry becomes more effective at leveraging material and process options in their designs, composite solutions will likely continue their growth trajectory in the aerospace industry providing lightweight aircraft that can be manufactured at scale.

© Victrex plc. 2021. All rights reserved.

Disclaimer

About the author

Jonathan Sourkes, Head of Sales - Aerospace at Victrex

Jonathan Sourkes, Head of Sales - Aerospace at Victrex, has over 13 years of experience in composite material application development. Jonathan has published numerous articles on the automated production of composites and the aerospace composite industry.

About the author