Performance meets processability

Not all thermoplastics are the same, material properties differ even within the specific class of high temperature, high-performance polyaryletherketone (PAEK) polymers. Our research shows that VICTREX AE™ 250 low melt PAEK unidirectional tape provides a larger processing window which allows improved press consolidation and forming with substantially identical physical and mechanical properties.

The thermoplastic panel is said to demonstrate that it is possible to achieve aerospace quality laminates with OOA processing in thicknesses not previously attainable, which may offer advantages in primary structural applications. In collaboration with Daher, the panel was made from VICTREX AE 250 LMPAEK UDT and an automated fiber placement (AFP) processing technique, followed by oven and vacuum or out-of-autoclave (OOA) consolidation.

Victrex, Daher, attain next-gen

thermoplastic aircraft panel milestone with 176-ply laminate,

32-millimeter-thick composite structure using VICTREX AE 250 low melt PAEK-based

thermoplastic composites.

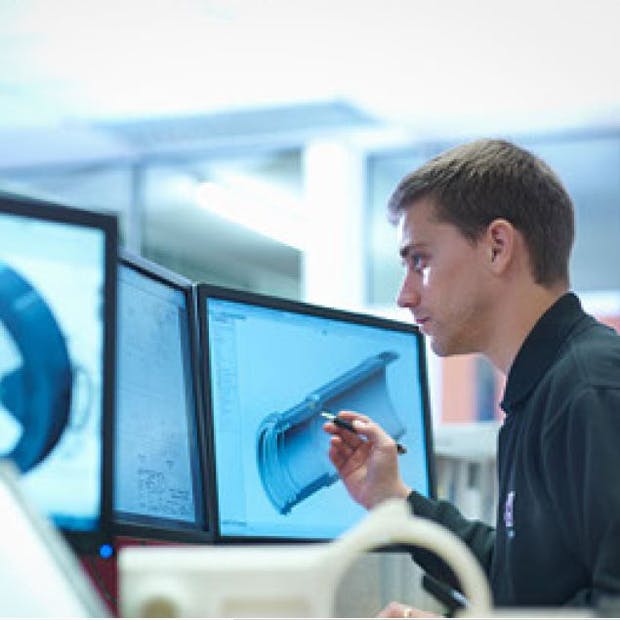

Victrex and Coriolis Composites unlock

efficiency potential for thermoplastic composite parts helping the aerospace

industry to create composite parts faster and more economically.

Designing hybrid parts with VICTREX AE 250 LMPAEK has the potential to reduce scrap rates, cycle times, part count, and

buy-to-fly ratios.

Victrex can help you design for stability in the most extreme aerospace environments. VICTREX™ PEEK and PAEK polymers have good elevated temperature performance, excellent mechanical properties, and chemical resistance to aviation fluids such as skydrol make, as well as low FST and lower density to common aircraft metals. These inherent properties combined with the design freedom to help consolidate parts for easier installation components for enhanced manufacturing efficiency make a compelling case to replace metal with PEEK and PAEK polymeric solutions.

Our high-performance PEEK and PAEK-based polymer solutions offer an exceptional combination of benefits to help aerospace OEMs, designers and processors reach new levels of cost savings, quality, and performance. Victrex solutions help lower weight, improve buy-to-fly ratios, and provide design freedom to optimise the design and consolidate parts resulting in reduced and or simplified installation, lower part count, and lighter components.

From the invention of PEEK over 40 years ago, Victrex has continually pioneered new PAEK-based polymers, materials and solutions that have transformed markets, delivering global impact in the toughest environments.

We bring transformational & sustainable solutions that address world material challenges every day.

Hi, do you have PEEK questions I can help with?