Manufacturing & Warehouse Network

Security of supply

With dedicated investment in state-of-the-art manufacturing centres and with the network of global warehouses, we provide our polymers where and when our customers need it.

Victrex invests in polymer production ahead of demand to meet our customer's needs. This includes our extensive PEEK and PAEK polymer production that delivers the world's highest capacity of 8,000+ tonnes. This is combined with our upstream integration of key raw materials, which ensure quality and supply control to deliver high quality PEEK and PAEK polymers.

State of the Art Manufacturing

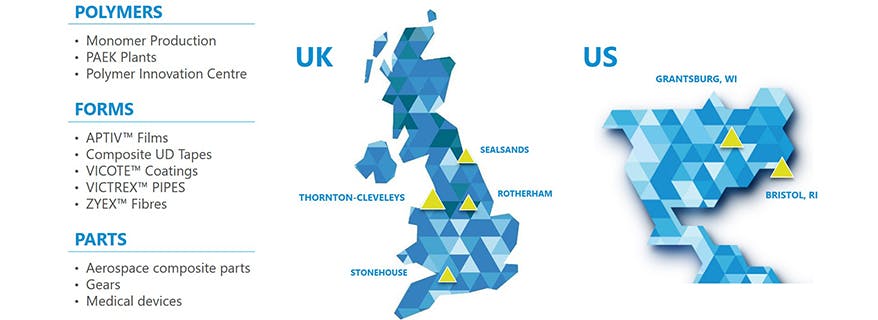

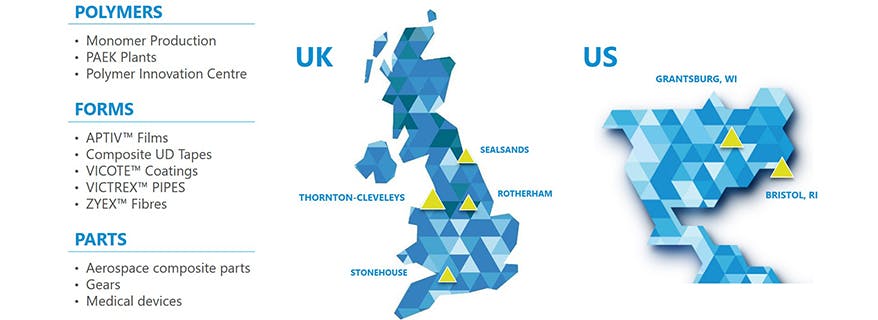

Polymers, Forms and Parts

VICTREX PEEK & PAEK POLYMERS

Victrex invests in polymer production ahead of demand to meet our customer's needs. This includes our extensive PEEK and PAEK polymer production that delivers the world's highest capacity of 8,000+ tonnes. This is combined with our upstream integration of key raw materials, which ensure quality and supply control to deliver high quality PEEK and PAEK polymers.

POLYMER INNOVATION CENTRE

Victrex Polymer Innovation Centre functions as an enabler for rapid prototyping of new parts and components, delivering batch manufacture of novel PAEK, and can support the continual improvement in quality and performance of existing products.

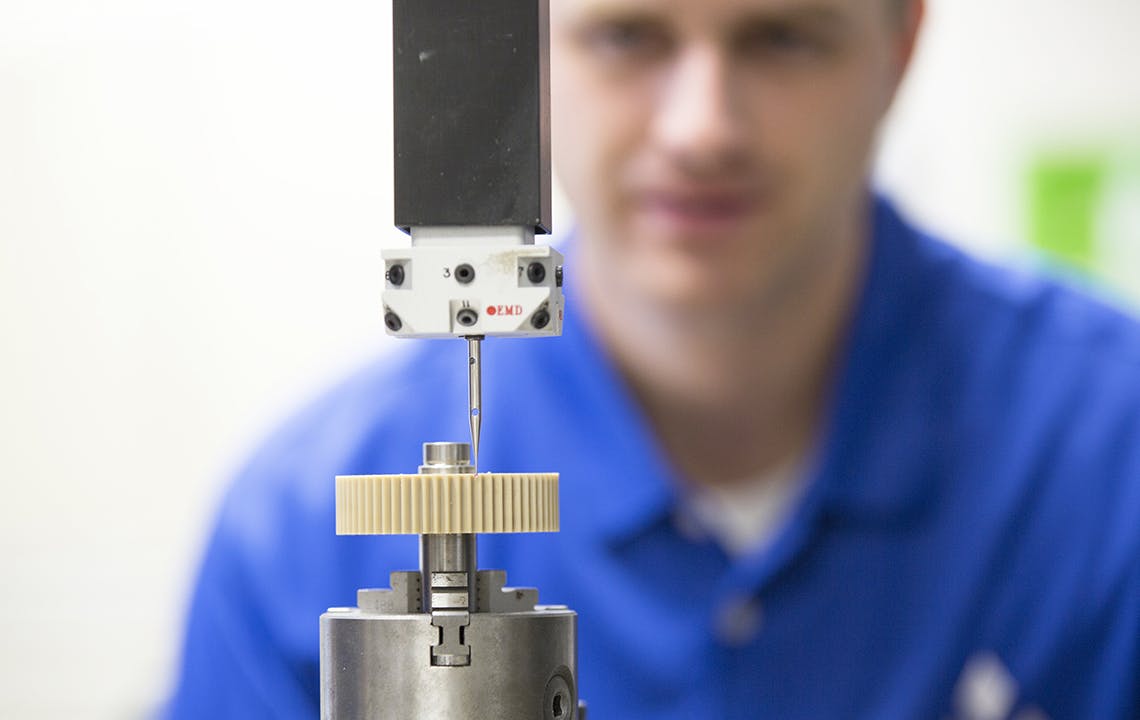

VICTREX GEAR SOLUTIONS

Our gear design and manufacturing facility in Grantsburg, USA is IATF 16949 certified. Capabilities here enables Automotive Tier 1/OEM customers to work with one partner from concept to commercialisation.

Supporting the development and testing of high-precision VICTREX HPG™-based gears, the Grantsburg site also manufactures these gears as a component for integration into larger systems, e.g. within the engine, transmission, pump, actuator and chassis.

AEROSPACE COMPOSITES PARTS

Our site in Rhode Island, USA is built for the sole purpose of manufacturing polyketone composite parts for commercial aerospace.

It is equipped with highly-automated manufacturing facility, certified with AS9100 and ISO 9001:2015, showing commitment to producing composite parts of the highest quality for the commercial aerospace industry.

The site also includes automated tape laying, consolidation, forming and injection moulding under one roof.

COMPOSITE UD TAPES

Our composites UD (uni-directional) tape facility and expertise in the development of PAEK-based composite solutions enables design and processing efficiencies for composites components development in the field of aerospace, energy and medical.

MEDICAL COMPONENT MANUFACTURING

We have clean room facilities dedicated for Invibio's medical component manufacturing and component testing, supporting our customers with the design, development and commercialisation of trauma fracture plates made of PEEK-OPTIMA™ Ultra Reinforced, a carbon-fibre-reinforced polymer.

Victrex have achieved this Certification for Integrated Business Planning (IBP). Companies that achieve Oliver Wight Class A excellence are considered top performers in their industries, consistently delivering sustainable business results, shareholder satisfaction and excellent customer service.

From the invention of PEEK over 40 years ago, Victrex has continually pioneered new PAEK-based polymers, materials and solutions that have transformed markets, delivering global impact in the toughest environments.

We bring transformational & sustainable solutions that address world material challenges every day.

Hi, do you have PEEK questions I can help with?