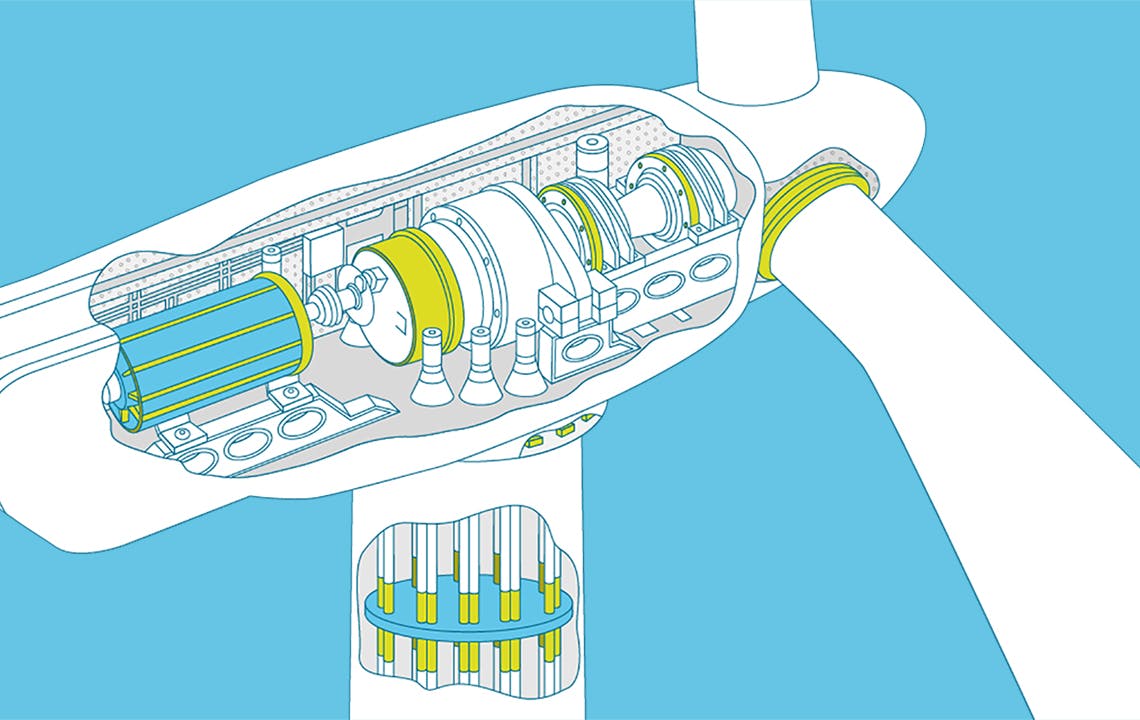

Innovative PEEK solutions can offer new ways to solve complex challenges in renewable energy

Up to 80% weight savings vs. metal helps to reduce stress on mechanical systems.

Extreme environments

Excellent resistance to moisture, chemicals, and environmental elements in wet offshore locations.