Lift off with less

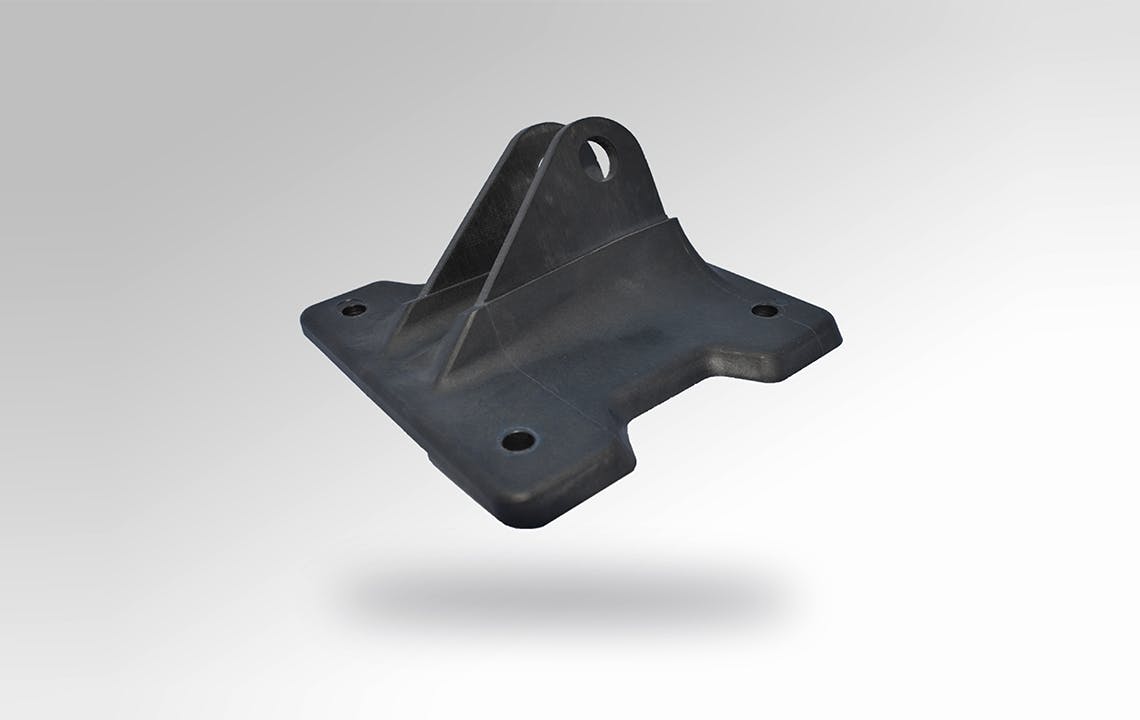

Loaded brackets

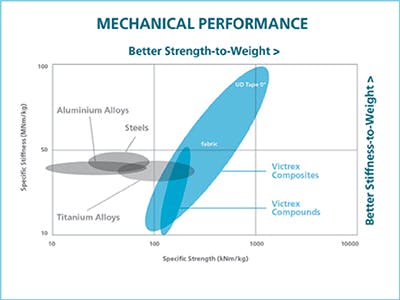

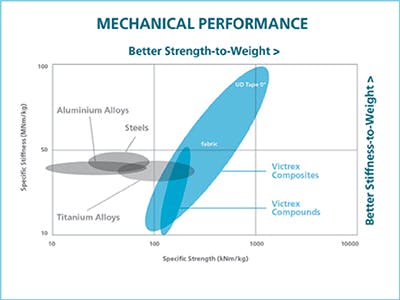

For parts requiring mechanical performance that cannot be achieved with injected moulded solutions alone, aerospace engineers can rely on overmoulded composite solutions made from VICTREX AE™ 250 LMPAEK. Efficient manufacturing, weight savings up to 60%, and up to 5x specific strength vs. metal are just a few of the benefits of replacing metal with hybrid overmolded solutions.

Designing hybrid parts with VICTREX AE 250 LMPAEK has the potential to reduce scrap rates, cycle times, part count, and

buy-to-fly ratios.

Hybrid Overmoulding

VICTREX AE™ 250 LMPAEK composite material solutions combined with advanced manufacturing processes such as hybrid overmoulding or automated fibre placement offer an attractive combination of cost reductions, weight savings, design freedom, strength, and production speed in next-generation components.

Our high-performance PEEK and PAEK-based polymer solutions offer an exceptional combination of benefits to help aerospace OEMs, designers and processors reach new levels of cost savings, quality, and performance. Victrex solutions help lower weight, improve buy-to-fly ratios, and provide design freedom to optimise the design and consolidate parts resulting in reduced and or simplified installation, lower part count, and lighter components.

From the invention of PEEK over 40 years ago, Victrex has continually pioneered new PAEK-based polymers, materials and solutions that have transformed markets, delivering global impact in the toughest environments.

We bring transformational & sustainable solutions that address world material challenges every day.

Hi, do you have PEEK questions I can help with?