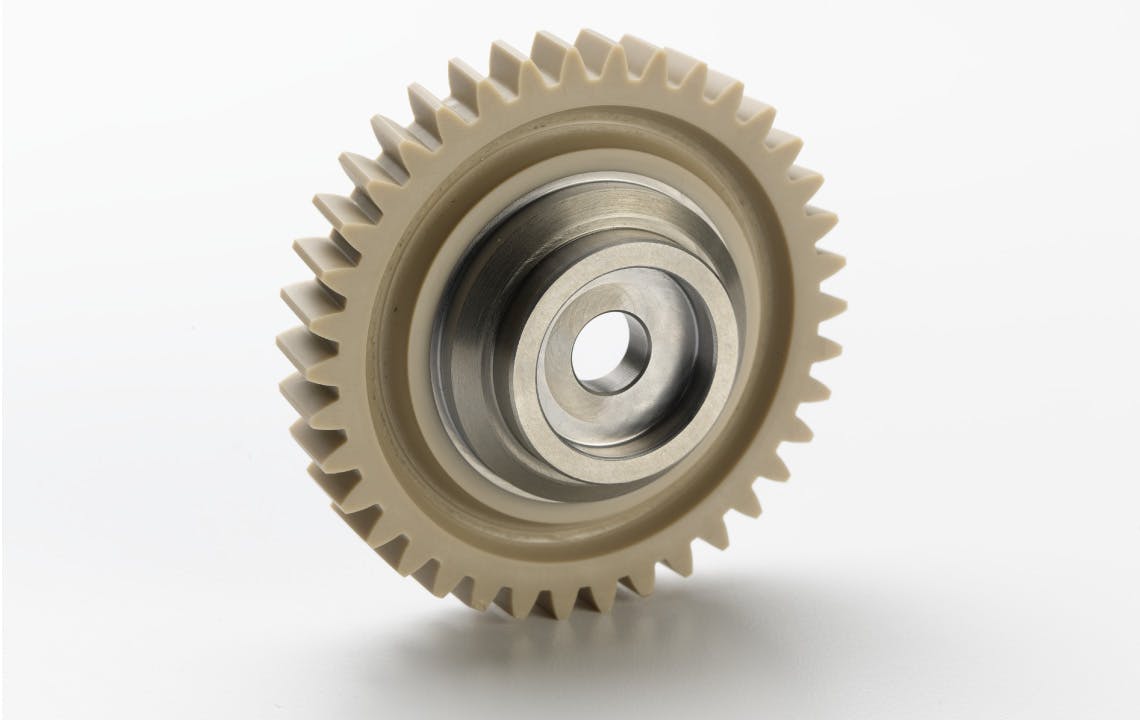

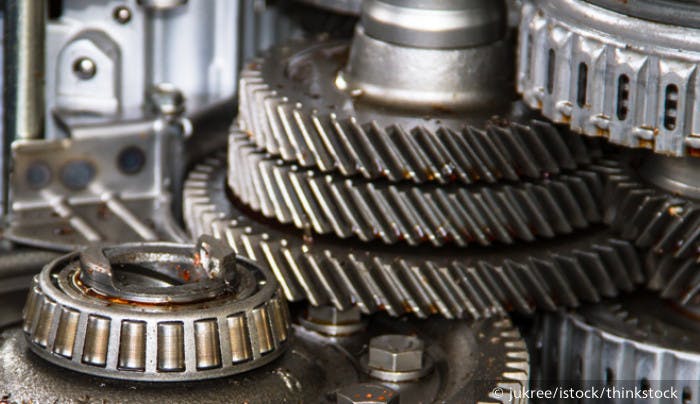

It's time to replace metal gears

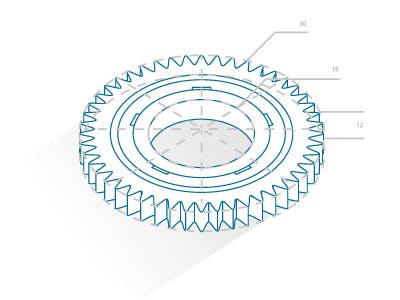

Our PEEK-based VICTREX™ Gear Solutions include gear design, prototyping, testing and manufacturing capabilities using VICTREX HPG™ polymers and help our customers gain a competitive advantage.

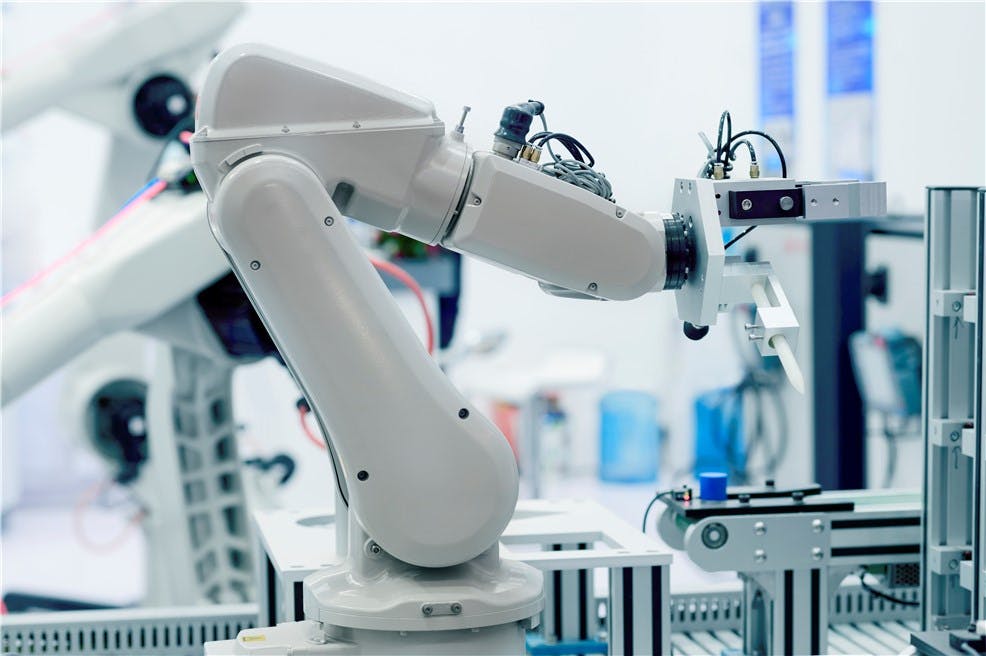

Transforming power into motion

Thermoplastic gears - a commercially viable solution for powertrain NVH improvement

Watch to learn all about durability data, NVH performance and cost saving potential.