Discover the Advantages of Our Innovative LMPAEK™ Polymer

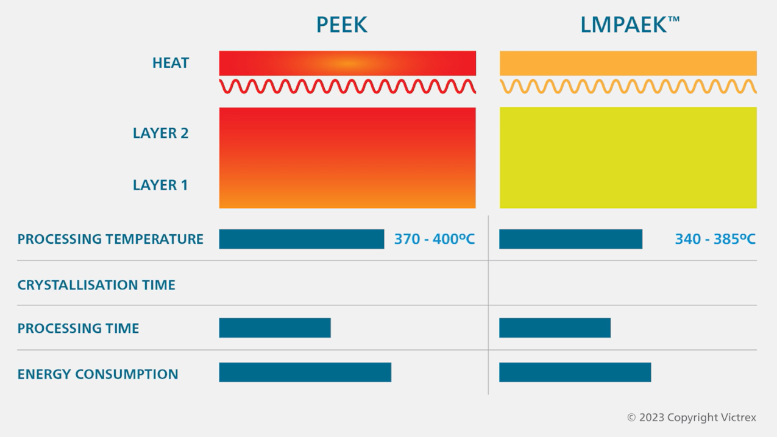

- Lower Processing Temperature: LMPAEK™ Polymer offers enhanced processing capabilities compared to PEEK, allowing for more efficient production.

- Optimised Crystallisation Rate: Designed for gradual crystallisation, LMPAEK™ Polymer excels in both advanced composite manufacturing and additive manufacturing applications.

- Ideal for Composite and Additive Manufacturing: The controlled crystallisation of LMPAEK™ Polymer enhances material performance in composite layups and 3D printing, offering greater precision and consistency compared to PEEK.

Lower Melting

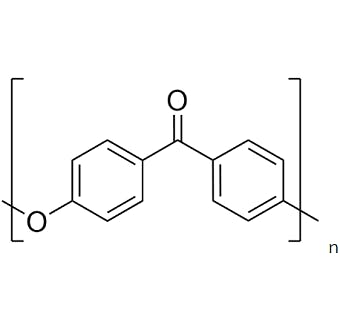

LMPAEK™ polymers melt 40°C lower than VICTREX™ PEEK

Ease of Processing

The wider processing window enables manufacturers to work with a broader range of temperatures without compromising the material's mechanical properties or performance. As a result, LMPAEK™ polymers offer improved flexibility in manufacturing, making them ideal for complex designs and precision applications

Redefining Advanced Manufacturing

LMPAEK™ polymers advance composite and additive manufacturing by offering high performance, easy processability, and design versatility, driving innovation across industries like aerospace and automotive