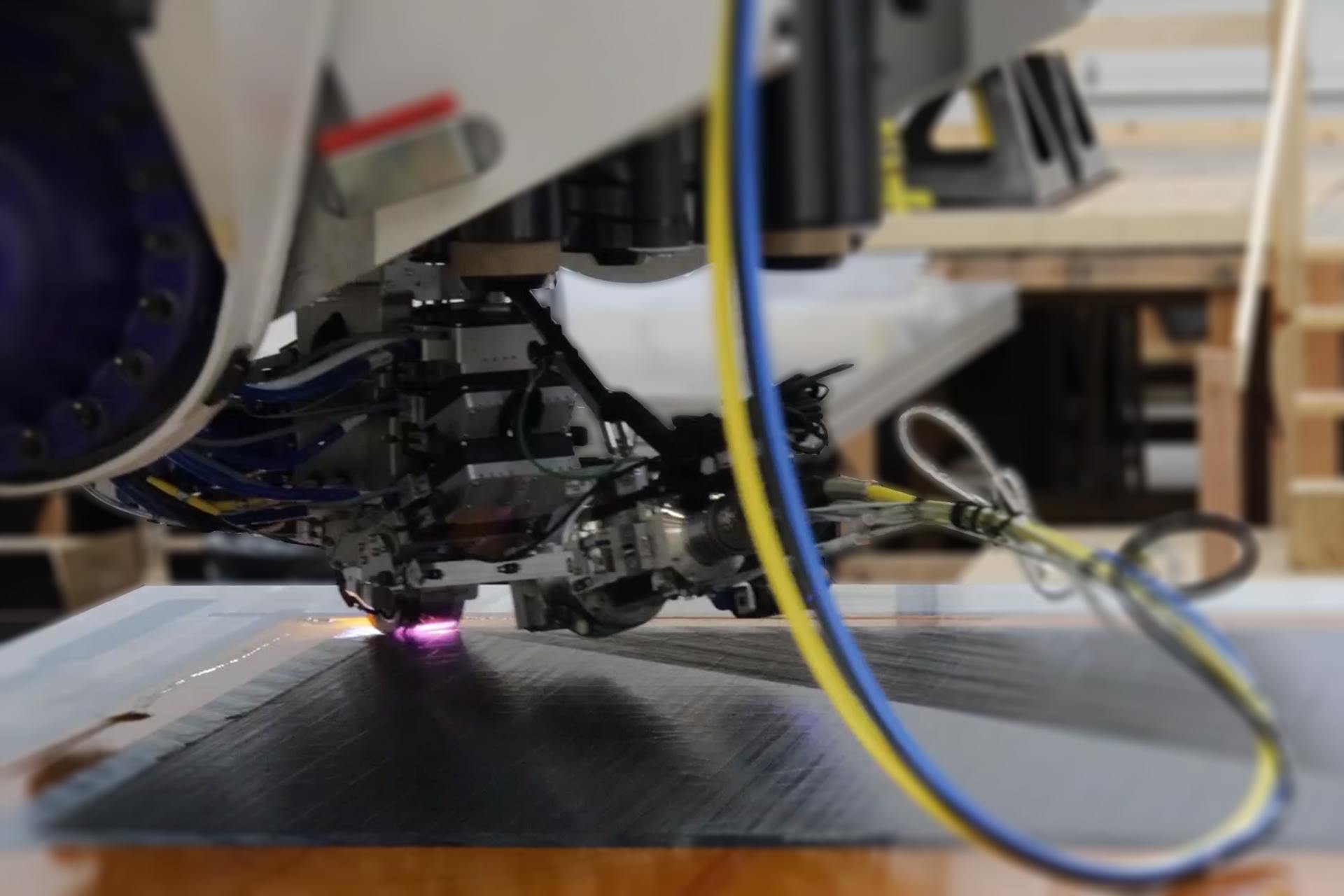

The next decisive step in the production of large structural components from thermoplastic composites for use in Aerospace has been achieved. Using their enhanced Automated Fibre Placement (AFP) processing technology, Electroimpact, a highly experienced provider of factory automation and tooling solutions, was able to increase laydown speeds of thermoplastic unidirectional tape (TP UDT) to 4000 inches per minute (IPM). The high-speed rates were possible by working together with Victrex, an innovative world leader in high-performance polymer solutions – and by relying on the unique properties of the company´s VICTREX AE 250 LMPAEK UDT.

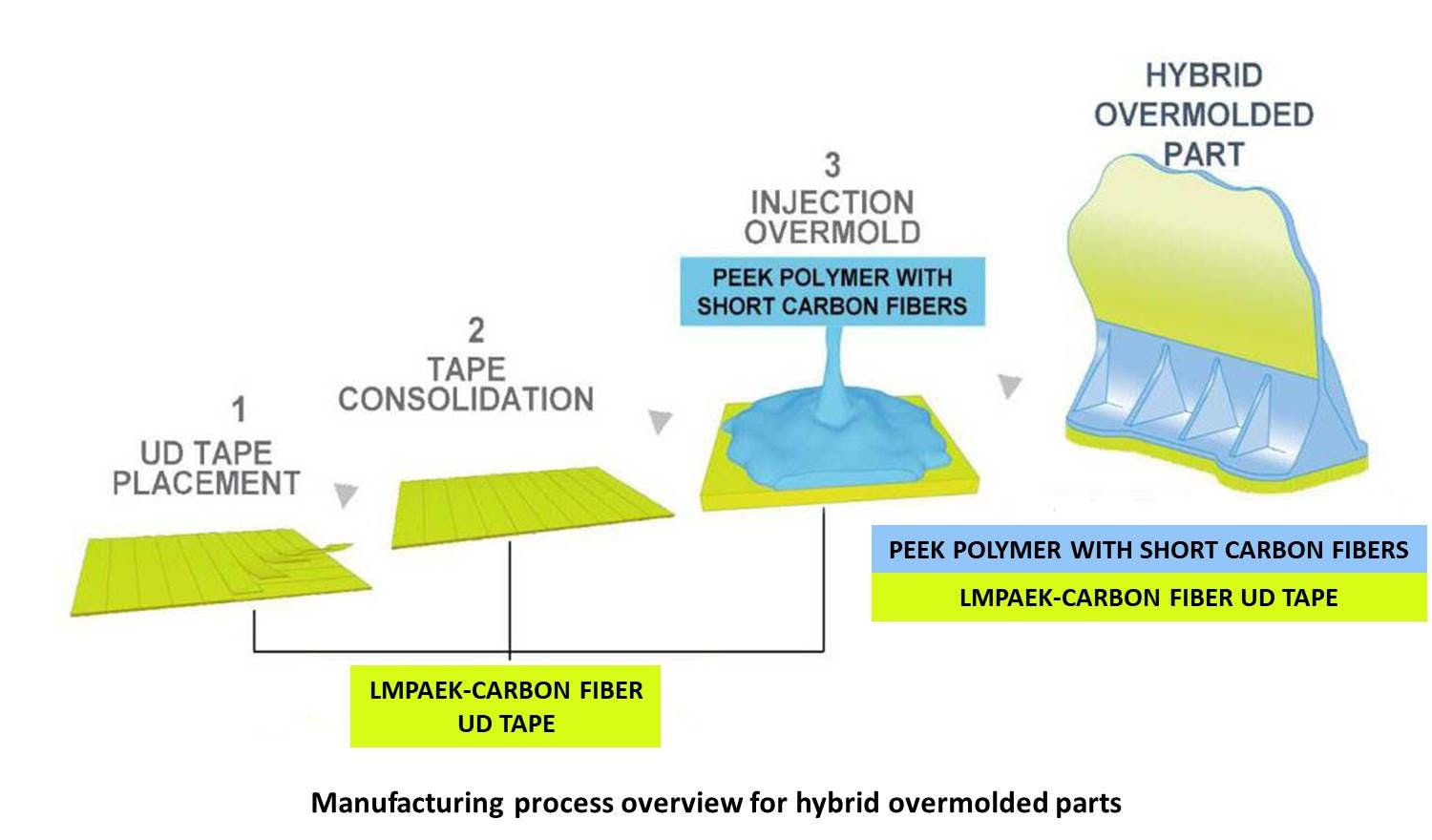

Currently, large composite structures in aerospace such as wings, and fuselage are virtually all thermoset based. However, the challenge with the thermoset composites is that they require a lengthy cure in an autoclave large enough for the structure. The autoclave is a production bottleneck and requires a considerable amount of energy to operate. With sustainability being an important driver for the aerospace industry, OEM’s and tiers are not only looking to improve fuel efficiency of aircraft but also at improving efficiencies throughout the supply chain. The substantial benefit thermoplastic composites offer has, for some considerable time, been investigated and this has led to an increasing adoption for the manufacture of smaller parts. Moreover, thermoplastic composites can be processed Out of Autoclave (OoA) so manufacturing processes have been developed to take advantage of their potential for high-speed production. Recyclability of thermoplastic composites is another major advantage as well.

“The significance of processing thermoplastic UDT at 4000 IPM layup speeds with the Variable Spot Size (VSS) Laser is, for the first time that we know of, that thermoplastics are able to achieve thermoset lay-up speeds. These developments can help eliminate the need for autoclave cure, offer major, and new, throughput advantages for thermoplastics.” explains Michael Assadi, Chief Engineer at Electroimpact.“

Electroimpact have enhanced existing AFP processing technology through the deployment of a new laser heating system with the potential to revolutionize thermal processing for the aerospace industry. Assadi adds: “We are really excited at Electroimpact to offer this new laser technology and using the high-performing LMPAEK composite material from Victrex on a broader scale to meet unmet customer needs. I’m convinced, that based on ongoing in-depth support from Victrex at every stage of the project, high speed production and high performance of the advanced VICTREX AE 250 UDT will enable the production of large-scale aerospace structural components in the years to come.”

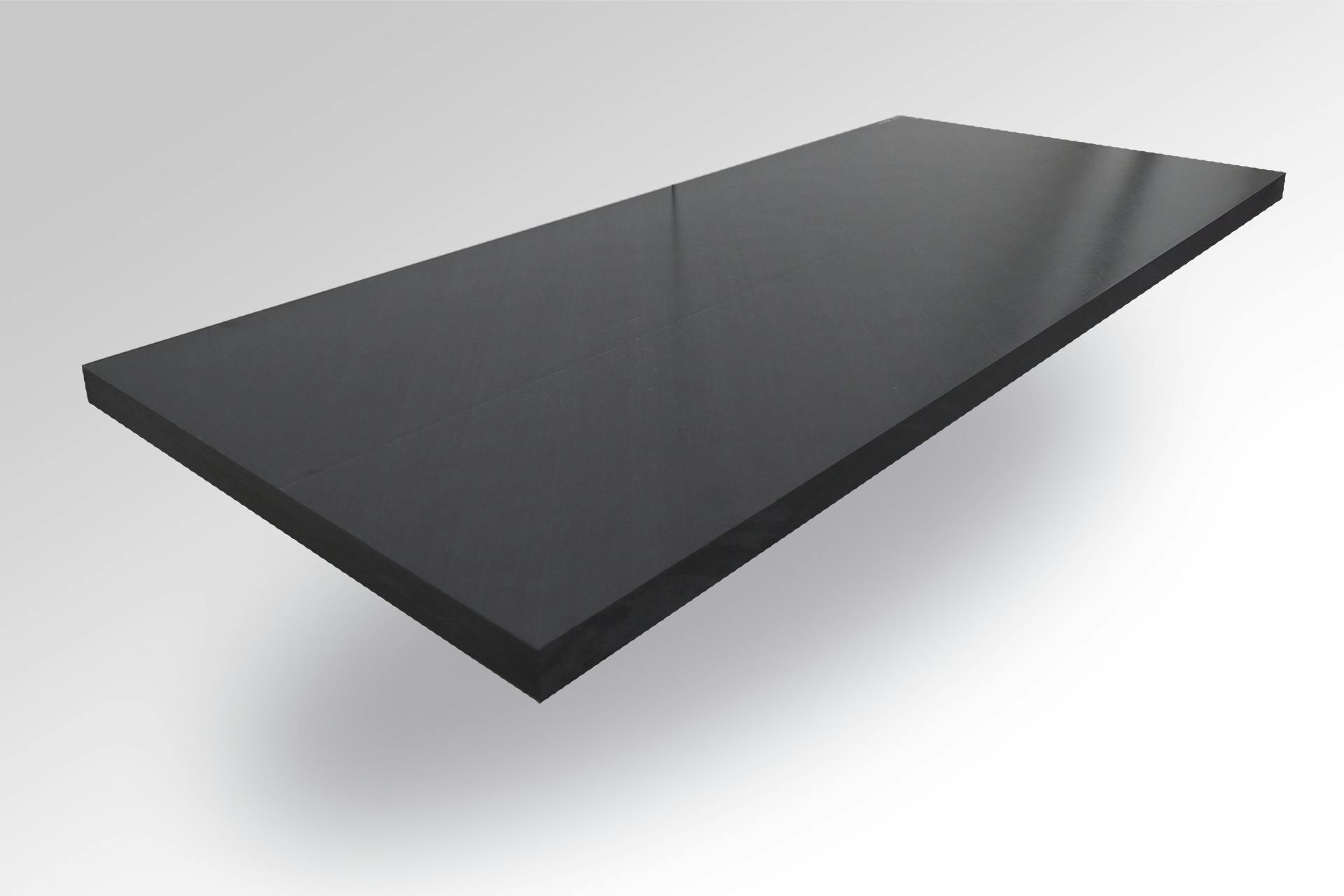

Electroimpact has already gone one step further and trialled in-situ production with VICTREX AE 250 UDT. A test program comparing several different materials demonstrated, that the Victrex LMPAEK UDT delivered the best performance producing porosity-free laminations, including the most dimensionally uniform and even distribution of fibre in the resin. As a result, a high-quality component can be produced without any additional processing steps after layup, eliminating the need for oven consolidation. In-situ manufacturing has long been considered the holy grail for aerospace composite structures.

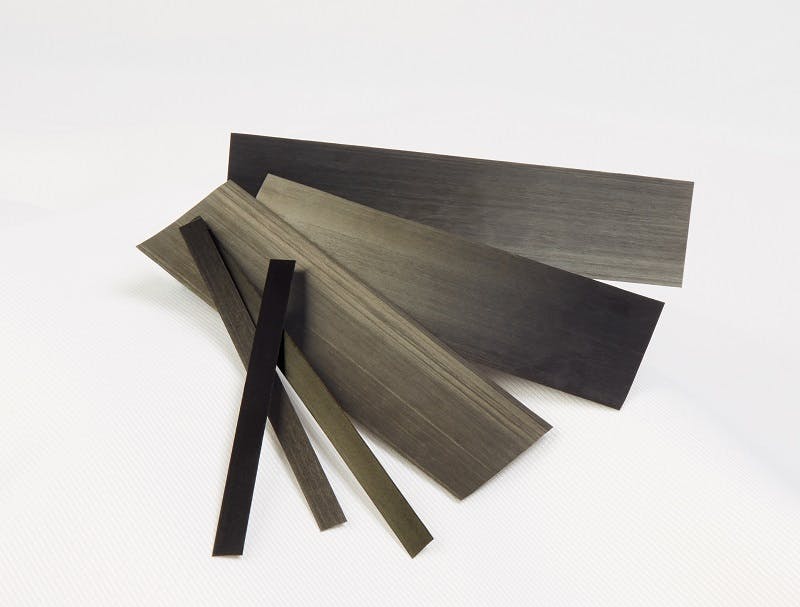

VICTREX AE 250 LMPAEK UDT: Highly efficient production for both, in-situ and Out of Autoclave consolidation

Key to the cooperation is the joint offering of optimised AFP process that delivers impressive time and energy-saving benefits in both in-situ and ‘Out of Autoclave’ (OoA) consolidation as compared to another polyketone UD tape intended for similar applications.

VICTREX AE 250 UDT is a novel, high-performance thermoplastic composite prepreg tape that was designed by Victrex to have mechanical, physical and chemical resistance properties typical of the Polyaryletherketone (PAEK) polymer family, such as PEEK, but with a 40 °C lower crystalline melting temperature, at only 305°C.

About Electroimpact

Electroimpact is a highly experienced provider of factory automation and tooling solutions. Our forte is the integration of automation and tooling into synergistic production solutions. We have a full-time staff of hands-on design engineers which is second to none in the industry. This allows for us to have an attention to detail which our competitors simply do not have the depth of talent to match, and also enables us to resolve issues very quickly for our customers as they arise. Our customer base includes Airbus, Boeing, Spirit Aerospace, Embraer, Kawasaki Heavy Industries, Mitsubishi Heavy Industries, Fuji Heavy Industries, Vought, Northrop-Grumman, Israeli Aircraft Industries, Xi’an Aircraft of China, Bombardier, and GKN among others.

Media Contacts

Victrex media contact

Melanie Embery, Head of Marketing Communications, membery@victrex.com, Phone +44 12538 98024

Corporate, Financial Media or Investor Relations Enquiries

Andrew Hanson, Director of Investor Relations & Corporate Communications, ahanson@victrex.com, Phone +44 12538 98121