For the development of efficient and durable aircraft floor brackets in its new regional jet ARJ21, COMAC (Commercial Aircraft Corporation of China, Ltd.) uses a combined material/service solution from Victrex. The company´s additional services, beyond supplying high-performing VICTREX™ PAEK polymers*, included simulation analysis, tools for design optimization and on-site processing support. As a result, greater design freedom, easier manufacturing and less weight compared to traditionally used aluminium led to the replacement of the metal.

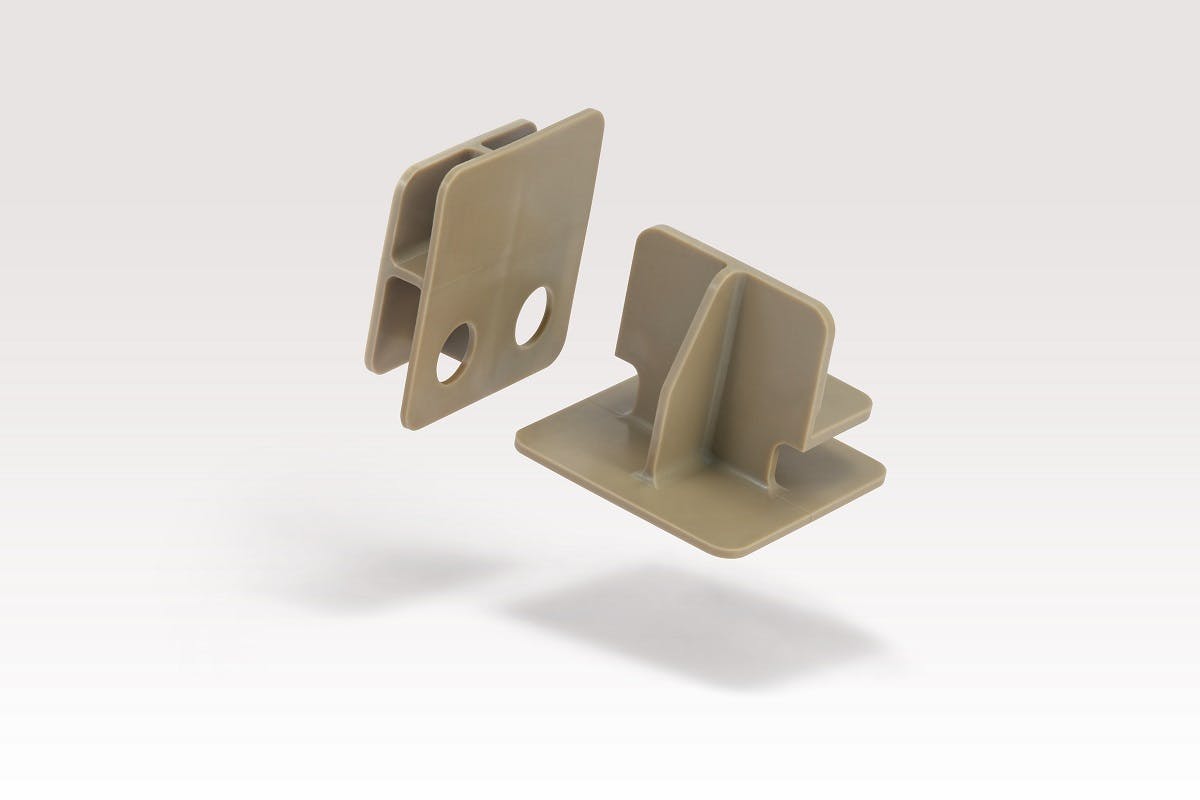

COMAC´s ARJ21 (Advanced Regional Jet for the 21st Century), a type of turbofan jet, is a short- to medium-range regional jet. Within the ARJ21 aircraft, internal loads are supported by various systems including structural beams. Floor brackets are positioned on these beams to provide support within a gap between the loaded beams and the aircraft flooring above. Typically, these brackets would have been manufactured in aluminium; the new PEEK polymer solution promotes increased production efficiency via rapid injection moulding of the part and is contributing to higher efficiency of the regional jet through weight savings and design improvements that simplify the installation process.

Victrex support and expertise beyond the polymer

“Today, weight reduction resulting in increased fuel efficiency, is absolutely essential and a critical success factor,” noted Dr. Bai Jie, Brackets Team Leader at COMAC. “This is common knowledge within the aerospace industry, but the full potential and processing efficiency of high-performing polymers are not. As a consequence, we have received support from Victrex as the PEEK experts with material and manufacturing knowledge. During the design process for example, their technical team delivered extensive and valuable support.”

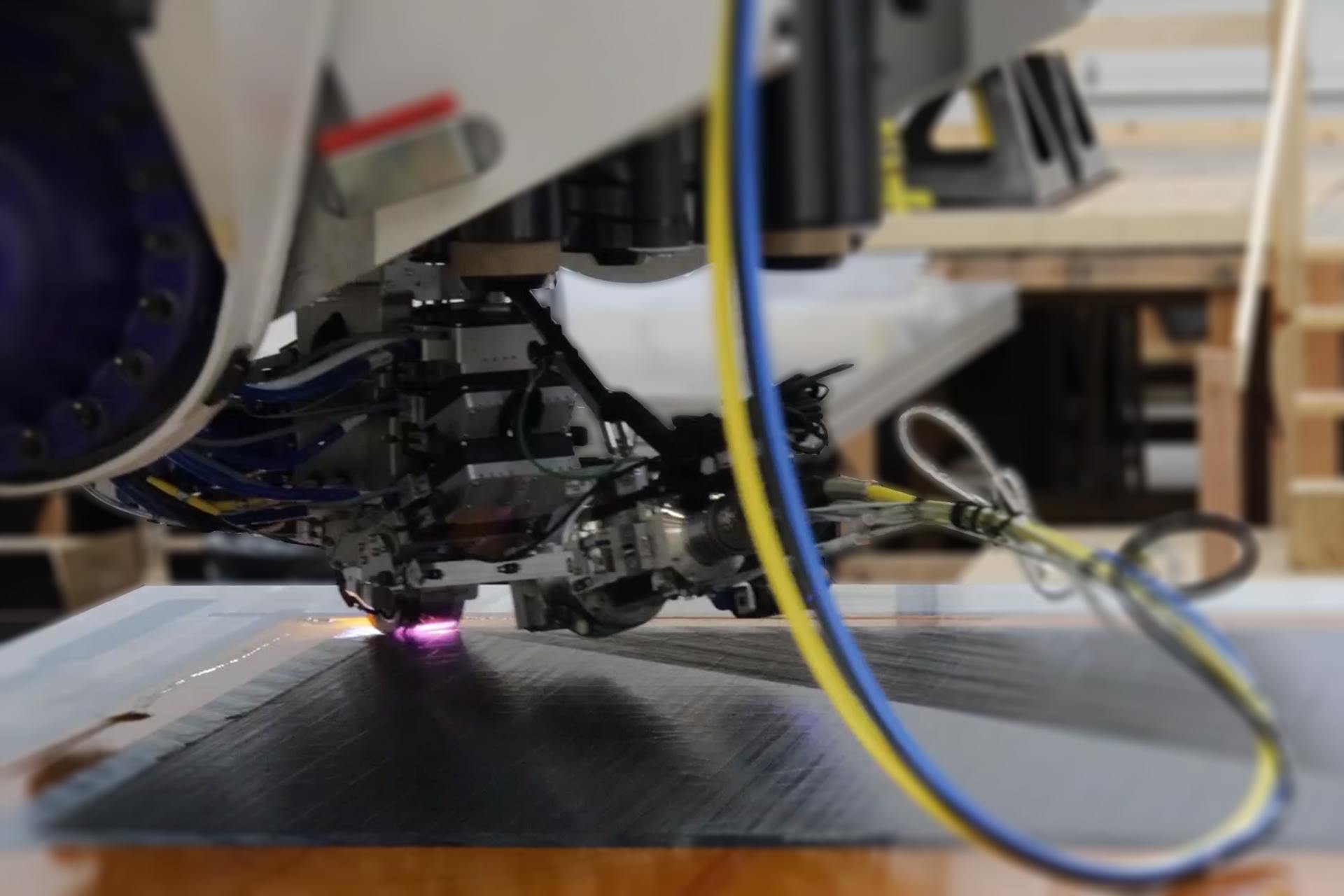

Specifically Victrex provided, as part of its extended services, the simulation analysis, the tools for design optimization, and on-site solutions whenever processing challenges arose. In engineering terms, each of the resulting brackets:

•

has a loading capacity of up to 6,000N

•

has a working temperature range of -55°C to 135°C

•

meets the FAR 25.853 requirements for flame, smoke, and toxicity

•

is lightweight (30% less compared to a corresponding aluminium bracket)

•

is a viable replacement for the same part manufactured in metal

The distortion tolerance of less than 0.2mm is considered optimal for installation in the case of the ARJ21 aircraft. Moreover, the floor brackets are extremely durable and offer an economical 30-year life-cycle, in an industry where safety and reliability are absolute prerequisites.

COMAC improving operating efficiency

On the one hand, it is COMAC's goal that airlines replace smaller regional aircraft with the new jet ARJ21 to enable more passengers to fly directly between longer distance destinations within China. On the other hand, the ARJ21 could be used in place of larger aircraft in order to increase flight frequencies and improve operating efficiency in line with airlines and passengers´ needs.

Switching from metals to

high-performance plastics for aerospace is now an established trend in this niche. VICTREX PEEK, an excellent choice for the manufacture of both loaded and unloaded aircraft brackets, can be used for components that need a good balance between strength and ductility, resistance to corrosion, and a low rating for flame/smoke/toxicity, while remaining non-conductive.

* PAEK, Polyaryletherketone, a family of high-performance thermoplastics, such as VICTREX

TM PEEK

Supporting information for performance claims in this press release is available on individual request from Victrex.