In the oil and gas sector for example, Magma´s m-pipe® technology serves as one of the prime examples of utilising an invention such as VICTREX™ PEEK thermoplastic composite to innovate. This subsea pipeline solution has been designed to reduce exploration and production costs and risks for demanding risers, jumpers, flowlines and downlines applications. At the end of 2016, Victrex invested a minority interest in Magma to further facilitate its adoption. Outstanding properties make m-pipe a cost-effective alternative to traditional steel and non-bonded flexible pipe. It requires minimal maintenance and, since it is not subject to corrosion, has a longer lifetime than steel.

Sealing solutions: Designed to improve efficiency and service life

Victrex recently launched a new cryogenics polymer, VICTREX CT 200. Specifically designed for dynamic sealing applications. This series exhibits improved sealing over a wider range of temperatures, compared to commonly-used materials such as PCTFE. It does so at low temperatures because of its greater ductility, and at high temperatures due to its superior creep resistance.

VICTREX CT polymers have also been shown to maintain better dimensional stability, with a lower coefficient of thermal expansion than incumbent material. The higher thermal conductivity of these Victrex polymers enables a fast response to temperature changes, ensuring the material is always engaged with the counter-surface. In addition, laboratory testing indicates that they may require less torque to actuate since they have a lower static and dynamic coefficient of friction compared to PCTFE. This results in less wear, higher performance and a potential for cost savings.

Seal rings, thrust washers, bushings and bearings made of PEEK are also used in many applications where they must withstand extremely high pressures, high temperatures, aggressive chemicals, and corrosive environments and consequently help to improve service life and reliability to eliminate costly downtimes. A case in point is thrust bearing pads for pumps; even after more than three years of operation, there is only minimal wear due to the tribological wear properties of VICTREX PEEK. In addition, power loss was reduced by up to 30%.

Innovation in composites earns 2019 JEC Innovation Award

Victrex´s considerable and long-term material and processing know-how decisively contributed to another PAEK-composite based innovation: German-based Herone´s all-thermoplastic drive-shaft system overmoulded with an integral gear. It was recently also recognized with a 2019 JEC Innovation Award. The application builds on three Victrex pillars: PEEK polymer; VICTREX AE™ 250 unidirectional tape (UDT) thermoplastic composite; and the hybrid overmoulding processing technique developed by Victrex.

Gearing up with PEEK polymers

Gear solutions replacing metals have shown a reduction in rattle and noise issues in automotive engine applications by up to 50% (3dB). Compared to powdered metal gears, the weight and moment of inertia is also considerably lower with VICTREX HPG™ gears, contributing to higher system efficiency in automotive applications. Victrex’s gear offering includes high-precision gear design, prototyping, testing and manufacturing capabilities to help customers gain a competitive advantage.

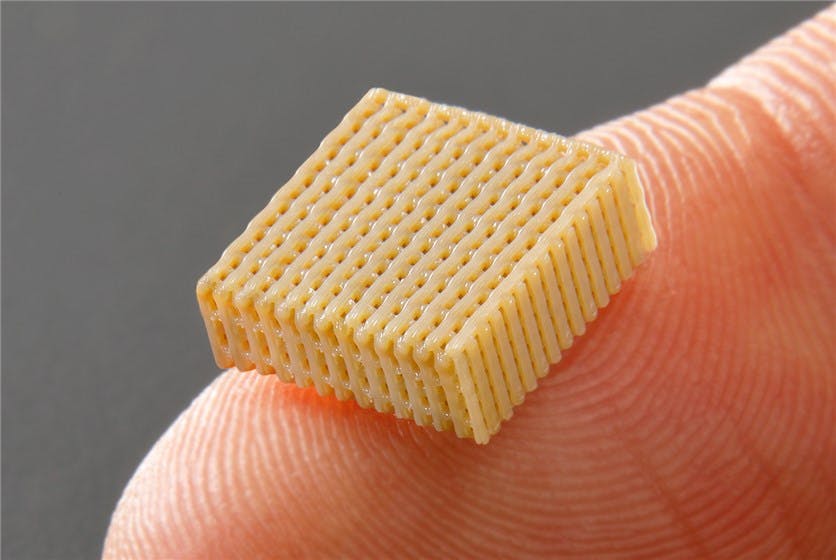

Proactive investments in the future open the door to further innovations including 3d printing

Continued improvement in application performance to accelerate innovation is an integral part of strategy and success at Victrex. Proactive investment in the development of next-generation thermoplastic solutions have, for example, resulted in:

- The completion of a multi-million world class ‘Polymer Innovation Centre’ in November 2017 to address materials innovation as well as different aspects of polymer R&D;

- The acquisition of Kleiss Gears (2015) and the fibre manufacturer Zyex (2017);

- A joint venture called TxV Aero Composites (2017) to manufacture Aerospace parts;

- UD Tape Composites Manufacturing

- Investments in PtFS (Production to Functional Specification), an innovative tooling design and processing technology from Surface Generation (2019);

- Minority share in Bond High Performance 3D Technology (2019) to help customers with an accelerated route to market for 3D printed PAEK* parts, building on the inherent strength of existing Victrex´s polymers and setting the path to produce functional, high strength parts which contribute to maximising performance of components.

High-performance VICTREX PEEK polymer supports multiple requirements

The inert properties of the versatile PAEK polymers are one main reason for their success. This family of polymers is ideally suited to extreme and demanding environments. Whilst alternative materials can meet specific needs, PEEKs are located at the top of the polymer pyramid and can support multiple requirements. Their properties include light weight, high strength, and high resistance to wear, high temperatures, fatigue and aggressive chemicals. Together, these outstanding properties contribute to enhanced fuel efficiency, extended part life, greater comfort (smooth operation, less noise), more design freedom and greater cost efficiency. A second important reason is that Victrex strategically focuses on this particular family of PAEK HPPs, and is committed to innovation, success and delivering total solutions to customers.

Visit Victrex at OTC Offshore Technology Conference 2019, May 6 -9th, Houston at booth #505.