Liquified Natural Gas (LNG) Growth

Globally, LNG is continuing to experience growth in demand as an attractive fuel option. With the significantly increased amounts of natural gas now being produced to be liquefied and transported around the world, a commensurate set of extreme low-temperature challenges are posed by LNG to the Energy Industry, an industry where polymers and elastomers are essential components of the supply chain, from liquefaction to gasification. The selection of suitable polymers for use at cryogenic temperatures is now an urgent issue.

Incumbent materials struggling in low temperatures

A mixture of hydrocarbons, predominantly methane but with varying levels of ethane, propane, butane and other naturally-occurring gases, LNG normally has a boiling temperature of between -166°C and -57°C, at atmospheric pressure. According to EN/ISO 16903:2015, many construction materials fail in a brittle manner when they are exposed to these very low temperatures.

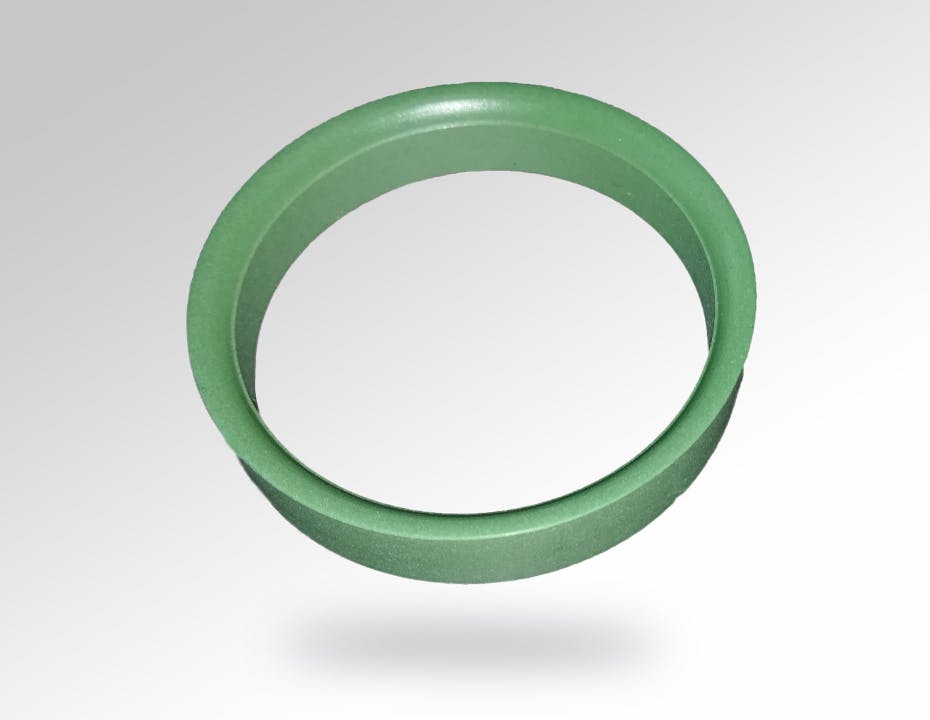

VICTREX CT polymers for cryogenic environments

VICTREX CT polymers offer processors and end-users a tailor-made solution to address the challenges of low-temperature environments. Victrex sealing material solutions are designed and tested for performance in cryogenic environments offering more consistent and reliable sealing across a broad temperature range compared to fluoropolymers.

Award-winning VICTREX CT polymers

VICTREX CT polymers are recognized as one of the most innovative materials at the 2023 Ringier Technology Innovation Awards for the Plastics Industry. The award recognizes VICTREX CT polymers for their proven performance in cryogenic environments and their potential to support reliable performance in sealing and valve applications.

VICTREX CT 200 polymer also received Industry Solutions Award at the China International Engineering Plastic Industry Innovation Conference in 2021 (2021中国国际工程塑料产业奖] 威格斯 VICTREX CT™ PEEK获创新行业解决方案奖).